Bi Metal Blade Meaning

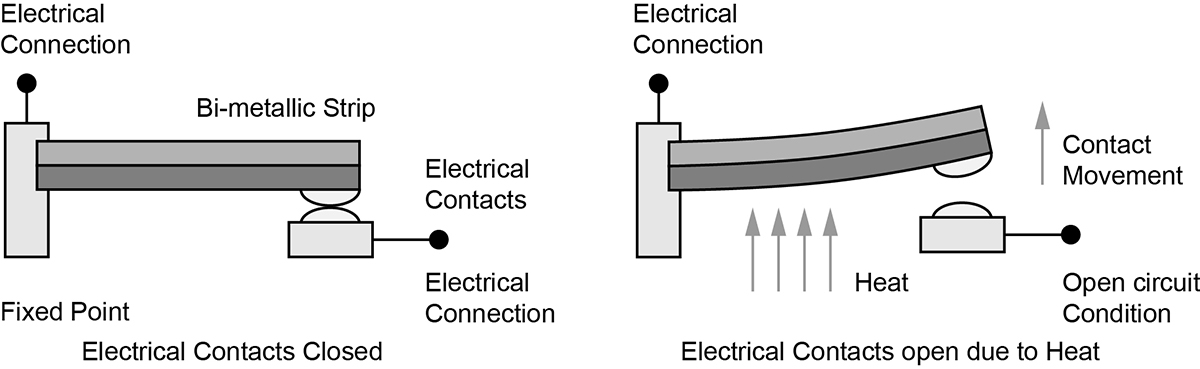

Metal metallic containing or made of or resembling or characteristic of a metal.

Bi metal blade meaning. That set is best suited for boring wholes through wood drywall and plastic. Why is it ideal. As stated above this is designed for cutting hardwoods but its teeth are ground and taper ground meaning they will provide a fine clean cut. This blade is fabricated from bi metal bim.

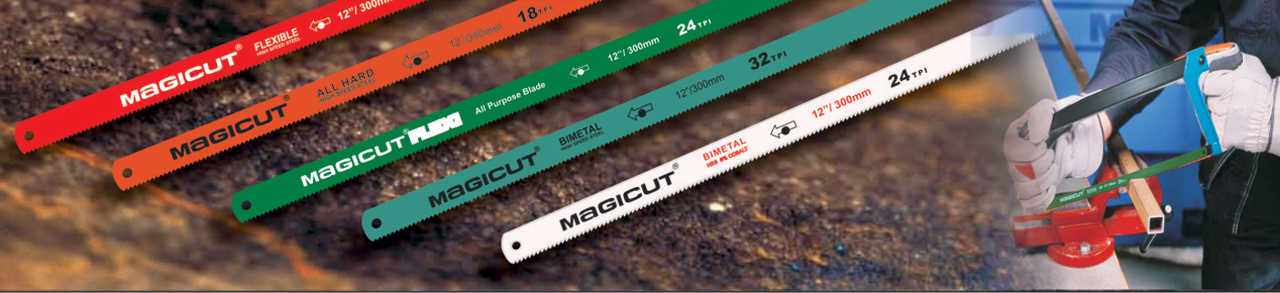

High speed steel tooth tips combined with flexible alloy steel backing material results in band saw blades that are the most cost effective choice for most metal sawing applications. What does the bi metal mean when referring to a utility blade. The bi metal terminology refers to how the utility blade is constructed. A wide variety of products are available to ensure optimal blade performance in your application.

That s a great answer for explaining bi metal. Following successful trials and hand arm vibration tests using cengar s premium bi metal saw blades master abrasives has announced it has been appointed as a distributor for cengar s range of high quality saws and accessories and says these fit well into master tool services package with products that are well suited to automotive and industrial applications. Instead of being a mixture of two or more metals like alloys bimetallic objects consist of layers of different metals trimetal and tetrametal refer to objects composed of three and four separate metals respectively. Bimetal refers to an object that is composed of two separate metals joined together.

Cermet tip imported from japan. Fin cut brand bi metal bandsaw blade is made of imported m42 high speed steel for edge and imported spring steel for backer by means of a series metal cutting saw blades with cermet tip special coating iso9001 quick detail. With a bi metal blade the edge of the blade is constructed of a high speed steel while the body of the blade is made of spring steel. Bi metal blades are a modern solution to cutting hard metals including steel.

A bimetal bar is usually made of brass and iron. These blades are produced for many different styles of saws including hacksaws band saws reciprocating saws and more. The two sections are welded together to form a single blade. If you wanted to cut metal with a whole saw it would have to be thin gauged metal no more than 18 gauge to preserve the integrity of the cutting tool any more than that and you would want to use a.

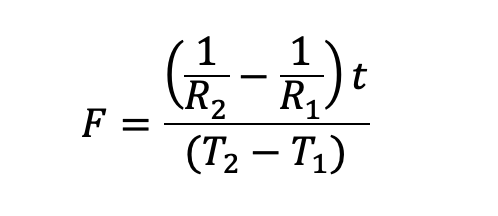

The teeth per square inch determine what a saw blade is meant for for.

.jpg)